Common-rail fuel injection system

Excellent performance and excellent efficiency are not a contradiction in terms: the common rail injection system enables BMW diesel engines to deliver improved fuel efficiency, lower emissions, improved acoustics and significantly smoother performance.

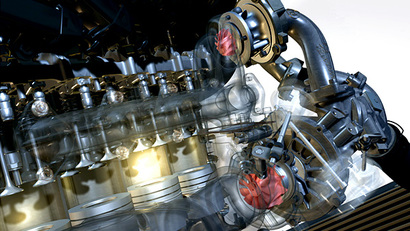

The flexible common rail injection system guarantees even quieter and more efficient BMW diesel performance. It exploits the principle that increased fuel-injection pressure produces finer droplets of fuel in the combustion chamber, which in turn results in better combustion. Instead of using individual injector pumps for each cylinder, the common rail system uses one central high-pressure pump (known as the rail). This leads to extremely fast, precise, electronically controlled injector valves.

Thanks to this sophisticated system, the diesel can be injected into the chamber in a number of different phases in each combustion process: a pre-injection introduces a small amount of fuel, followed by the main injection, and then follow-up injections if required. The pre-injection phase ensures that the combustion-chamber pressure increases evenly, which reduces engine noise. The follow-up injections burn any remain particulates and treat the exhaust gases.

Together with high-performance digital engine management and precisely designed injection valves, the common rail injection system delivers significant improvements in fuel consumption and enhances smooth engine running.

Back to list

The flexible common rail injection system guarantees even quieter and more efficient BMW diesel performance. It exploits the principle that increased fuel-injection pressure produces finer droplets of fuel in the combustion chamber, which in turn results in better combustion. Instead of using individual injector pumps for each cylinder, the common rail system uses one central high-pressure pump (known as the rail). This leads to extremely fast, precise, electronically controlled injector valves.

Thanks to this sophisticated system, the diesel can be injected into the chamber in a number of different phases in each combustion process: a pre-injection introduces a small amount of fuel, followed by the main injection, and then follow-up injections if required. The pre-injection phase ensures that the combustion-chamber pressure increases evenly, which reduces engine noise. The follow-up injections burn any remain particulates and treat the exhaust gases.

Together with high-performance digital engine management and precisely designed injection valves, the common rail injection system delivers significant improvements in fuel consumption and enhances smooth engine running.